Bitumen Roof Felt Adhesive - Black Jack - 25 Litres EVERBUILD 90425

Bitumen Roof Felt Adhesive - Black Jack - 25 Litres Black Jack Roof Felt Adhesive is a cold applied, black oxidised bitumen based adhesive used to bond roofing felt to itself, concrete, asphalt, metal, wood and similar surfaces. Also suitable for...

Add Item To Project

Add Bitumen Roof Felt Adhesive - Black Jack - 25 Litres EVERBUILD 90425 to a project and build a price list for your next project!

Login to My AccountOR

Create AccountBy creating an account you are able to save items and create project lists.

Best Prices

|

£79.99Best Price |

Visit Site |

|

£79.99 |

Visit Site |

The prices shown are available online and may not reflect in store. Confirm prices before visiting store.

Get Price Change Alerts

Be the first to know when prices change

Login to My AccountOR

Create AccountBy creating an account you are able to save items to your watch list.

Add Item To Project

Add Bitumen Roof Felt Adhesive - Black Jack - 25 Litres EVERBUILD 90425 to a project and build a price list for your next project!

Login to My AccountOR

Create AccountBy creating an account you are able to save items and create project lists.

You may also like

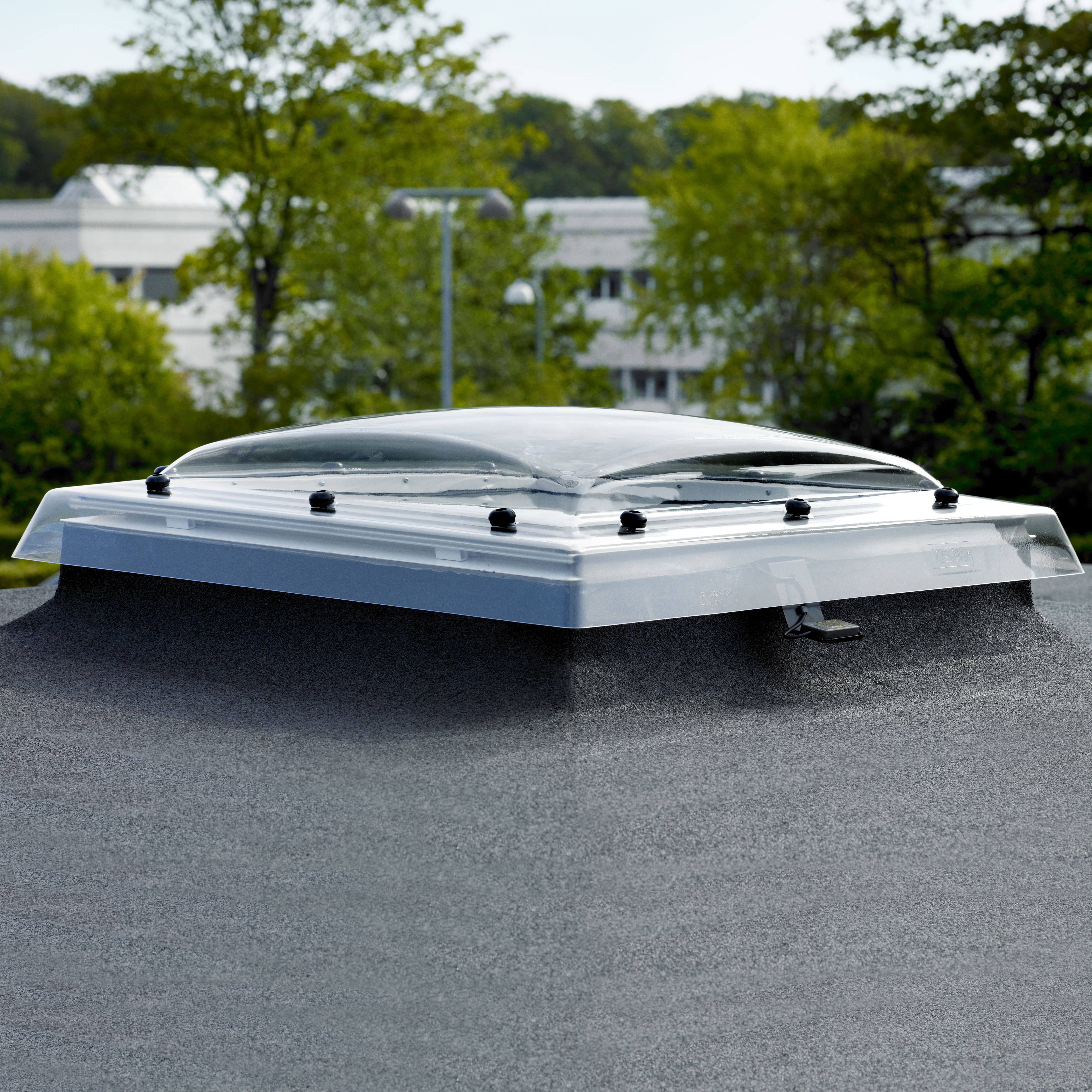

Velux White Pvcu Fixed Flat Roof Fixed Window (H)780mm (W)780mm (L)780mm

£510.00

Cheapest at B&Q

Sandtoft TLE Dry Verge Unit Right Hand - Antique Slate 6040080

£5.16

Cheapest at Roofing Superstore

Axiome Polycarbonate Sheet - 16mm x 1700mm x 4000mm Opal

£201.14

Cheapest at buildingmaterials.co.uk

Cwt Y Bugail County Grade Welsh Slate Roof Tile in Blue/Grey - 500mm x 250mm Natural Slate Roofing Superstore CWT-Y-COUNTY-5025

£7.07

Cheapest at Roofing Superstore

Compare Thousands of Products and Tools in Seconds

In need of more supplies? We've got you covered! Explore thousands of products from your favourite suppliers, all under one (very sturdy) roof.

Create Account